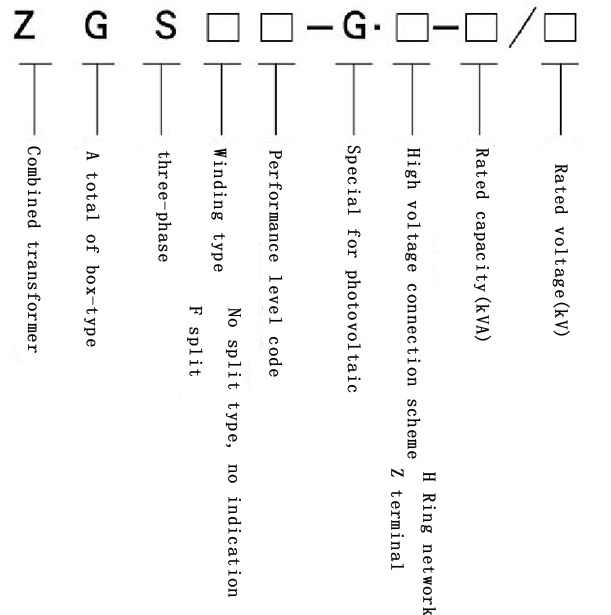

ZGS-10 (40.5) kV PV boost substation

Contact:

Combined American box transformer is the transformer body, high voltage load switch, fuse and other components together in the transformer oil tank, because immersed in oil, the component volume is greatly reduced, the structure is more compact, convenient installation, flexible. Fully insulated, fully sealed structure, safe and reliable, easy to operate, maintenance free. Widely used in residential areas, high industry centers, factories and mining enterprises, airports, stations, schools and other places.

An overview of the

This product is the absorption of foreign latest advanced technology, combined with the actual situation of domestic research and development, the whole product has small volume, easy installation and maintenance, low noise, low loss, anti-theft, overload capacity, full protection and other characteristics.Applicable to solar photovoltaic, wind power generation and other places.

ZGS-10 (40.5) KVKV series American pre-installed box type substation, suitable for 10kV, 35kV ring network power supply.

This product conforms to the following standards :GB/T17467-1998 “High-voltage and Low-voltage Preinstalled Substation”, DL/T537-93 “Ordering Technical Conditions for 6-35kV Box Substation”.

Operating environment conditions

◇ Altitude does not exceed 2000m (Altitude over 2000m requires capacity reduction, contact with the factory when manufacturing).

◇ Ambient temperature :-40℃~+55℃

Relative mixing degree: the daily average is not more than 95%, the monthly average is not more than 90%;

Installation place: no fire, explosion danger, chemical corrosive gas and well ventilated place, the ground Angle is not more than 3°.

Functions and features

Full insulation, full sealing, less maintenance, reliable to ensure personal safety;

Compact structure, the volume is only 1/3-1/5 of the same capacity of European change, low height;

◇ The sub-box structure can be used to avoid the pollution of oil in the transformer oil tank

The high voltage side adopts double fuse for full range protection, which greatly reduces the cost:

Available for ring network, also can be used for terminal, cable head can be in 200A load current emergency plug;

The box adopts honeycomb double sandwich composite plate, which has the function of temperature insulation and heat dissipation.

◇ The low voltage side is equipped with electronic phase loss protector, which can quickly break the main feed switch when the abnormal voltage occurs in the system.

High-voltage side oil-immersed load switch or SF6 load switch can be upgraded electrically, which lays a foundation for realizing the automation of distribution network.

◇ Use oil-immersed S9 or S11 series transformer with better performance.

Main technical parameters

|

Name |

Unit |

Technical parameter |

|

|

1 |

Rated Voltage |

kV |

10(12、24、35、40.5)/0.4、0.69、0.8 |

|

2 |

Maximum working voltage |

kV |

40.5 |

|

3 |

Rated frequency |

Hz |

50/60 |

|

4 |

Rated capacity |

kVA |

50-6300 |

|

5 |

1min power frequency withstand voltage |

kV |

68 |

|

6 |

Lightning impulse voltage |

kV |

100 |

|

7 |

Cooling method |

Oil-immersed self-cooling |

|

|

8 |

High voltage backup fuse breaking current |

kA |

50 |

|

9 |

Plug-in fuse opening current |

kA |

2.5 |

|

10 |

Ambient temperature |

℃ |

-40-+55 |

|

11 |

Temperature of coil is allowed to rise |

℃ |

65 |

|

12 |

No load regulating pressure |

±5% or ±2*2.5% |

|

|

13 |

Noise level |

dB |

50 |

|

14 |

Protection Class |

IP54 |

Cases of variable structure

The structure of the product box is composed of high pressure interval, low pressure interval and oil tank interval.The high pressure interval includes high voltage cable accessories, load switch, no-load pressure regulating tap switch, insert type fuse, pressure relief valve, oil level gauge, oil temperature gauge and oil discharge valve.The low voltage interval includes a low voltage bushing, a low voltage meter, a circuit breaker and a capacitor compensation.Transformer windings and iron cores, radiators, high-voltage load switches and fuses are included in the tank interval. According to the needs of the scheme, the variable structure of the tank can be designed with finished font or eye font, as shown in the figure below.

Instructions for

Operation of load switch

The oil immersed load switch used by the American box transformer has three kinds of two stations, four stations T type and four stations V type according to the different functions it realizes. One of them is available for choice. The operation of the three kinds is as follows:

The four-station V-type load switch is shown in Figure 2. The power plate structure is a “V-type” structure. See the black part in the figure., Ⅱ “for the outlet and inlet line of ring network power supply, the” T “for the backup fuse, fuse inserting transformer high voltage into the line.Loop load switch switches the network with load.The four working states of the load switch:

1, “I – Ⅱ – T”, the “I” and “Ⅱ” two network connectivity, transformer have electricity;(Substation serves as a ring network)

2. When “I-T” is in position, “I” network is connected with the transformer;(Substation starting terminal)

3, “Ⅱ – T” position, “Ⅱ” network and transformer connected;(Substation starting terminal)

4, “O”, “I, Ⅱ” net and transformer are disconnected;(All without electricity)

Insert the load switch shaft with the special operation handle, and rotate about 130° clockwise or counterclockwise. Each time the load switch operates, the power plate rotates in one gear.Example of switching operation: switch from power supply “I” to power supply “II”.

A. Insert the special operation handle into the switch shaft;

B. a clockwise switch, the switch “V” type blade in the “I – Ⅱ – T” position;

C. clockwise rotation again, this time “V” type blade in between “| – T” for power supply, power supply “|”Operation completed.

Operation method two:

A. Insert the special operation handle into the switch shaft;

B. Rotate the switch counterclockwise once, and then the “V” blade of the switch is in the “O” position:

C. counterclockwise rotation again, this time the “V” type blade in between “Ⅱ – T” for power supply, power supply “Ⅱ”Operation completed.

Using the above two methods can be completed from the power “!”Conversion to “Ⅱ” power supply power supply, but the second method is safer and more reasonable.The power supply “I” will not be resupplied after being cut off. At the same time, if the power supply “I” fails, it will not be closed to the fault.And use method, a dual power supply, will appear when the power supply “I” into power “Ⅱ”, if the power supply different causes such as the fault phase.

The working principle of the four-station “T” type load switch is shown in Figure 3, and its operation principle is the same as that of the V-type.

Two station terminal load switch

Its structure is shown in Fig. 4, in which “I” is connected to the high voltage inlet terminal.User during operation, the special operation handle is inserted in the load switch shaft, counterclockwise rotation “90 °”, load switch turn to “points” gate location, terminal load switch used in terminal power supply way to cut off the transformer branch, or changing the insert fuse molten core while you work, so the terminal load switch points, only two position, and because of the smaller, the operating force is small, use very convenient operation within the tank to reduce pollution, recommend that users before operating load switch off the low voltage main switch and outlet switch to low voltage side load.

Cable head

A. The high-voltage inlet and outlet lines of the pre-installed substation adopt cable inlet and outlet lines, and the high-voltage power supply is led out of the tank by the epoxy pouring insulation bushing. In order to facilitate the test of the manufacturer and the acceptance test of the user, the insulation bushing itself has the ability to withstand power frequency voltage and lightning shock voltage.

B. Select the time-type or T-type cable head that matches the cable section, install its internal and external surfaces and surfaces, and install them in accordance with the special installation specifications of the cable working area.See the manual for installation of cable head.

Plug-in fuse is an element for external replacement of the melt core. When replacing, first pull the button of the pressure relief valve of the upper oil tank to balance the pressure inside and outside the oil tank.In order to ensure the safety of operating personnel and equipment, insert fuse plug without load, so the low voltage switch power first, with removal of the low voltage side all load, reoccupy handles the load switch to switch to the power supply and transformer disconnect position, and then use the handles on the handles will fuse unscrew, to about 90 degrees of rotation, to eliminate the adhesion effect between packing and the outer wall, and syncline melt of pull out fuse above the 70-80 – mm, stay for a few seconds, after being on the melt flow off some, and then pull out the melt, so as to avoid oil droplets on the fuel tank of the other element: used to clean cotton cloth to clean the melt surface to replace the